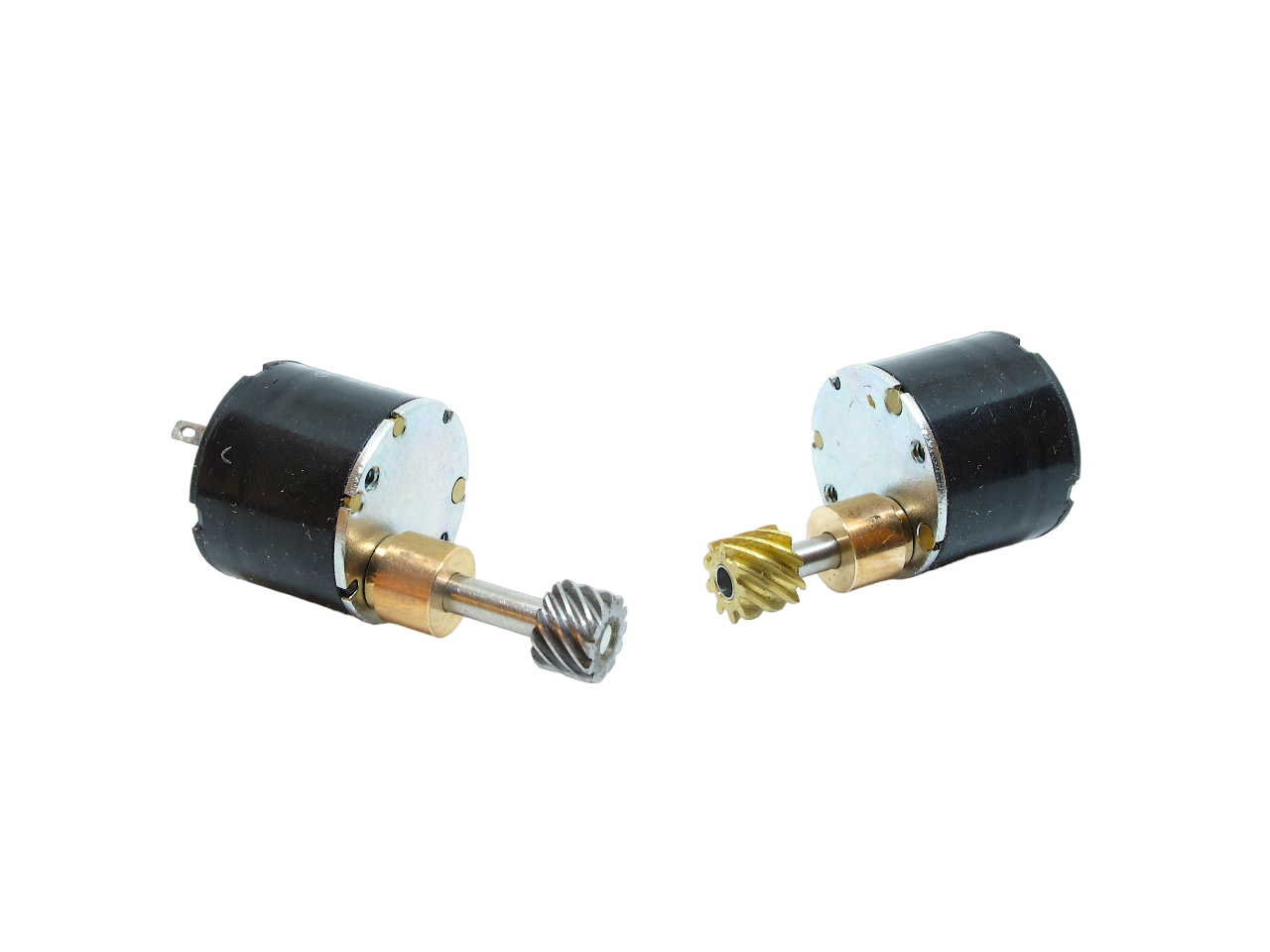

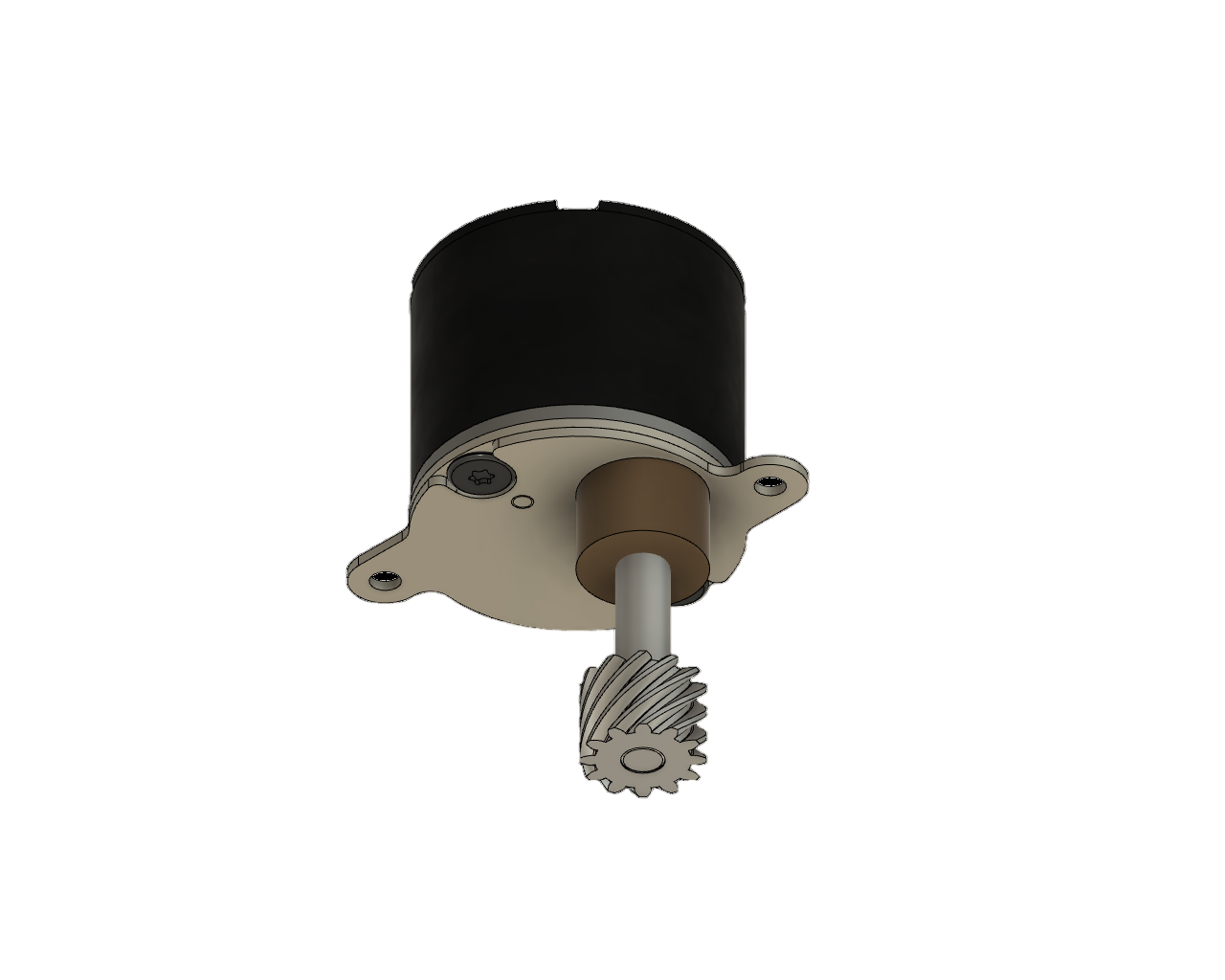

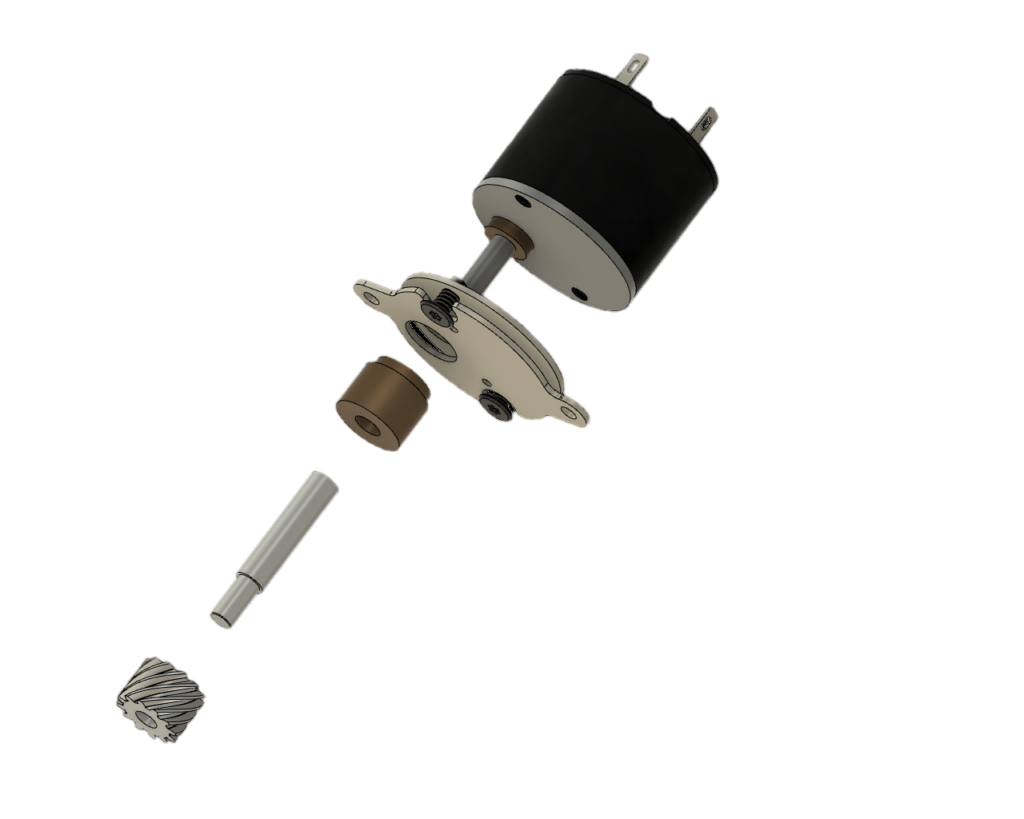

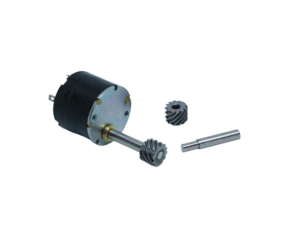

Following on from the stainless steel extension bushings for the Gmeinder's mechanical chassis, I also received the machined bronze bearings. These bearings are intended to provide a major improvement to facilitate the assembly of the geared motor, and in particular the adjustment of the centre-to-centre distance of the gears, which was somewhat tricky. The gearmotor will now be positioned automatically, by the bronze bearing on the one hand, and the photoetched nickel-silver frame on the other, whose hole is positioned precisely at the centre-to-centre distance of the gears in relation to the axle.

This makes positioning the motor gearhead much easier when it comes to adjusting the centre-to-centre distance of the gears. There's no need to worry about adjusting the centre-to-centre distance, just insert the motor gearbox assembly into the chassis!

In addition, this bearing, welded to the gearmotor support and positioned precisely on the brass bearing at the output of the gearmotor shaft by means of its counterbore, will reduce the 'play' and strengthen the gearmotor.

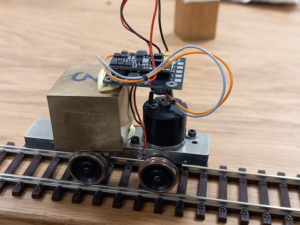

This improvement is also planned for the MD2 transkit. A prototype has been installed and tested on a test chassis, which gave full satisfaction after more than a dozen hours of operation.